Engineering Techniques

We strictly control over all process to maintain its quality from

mold design to robotic grinding and deburring.

There are more than 30 CNC machines in house and they produce more

than 100,000 different types of parts currently.

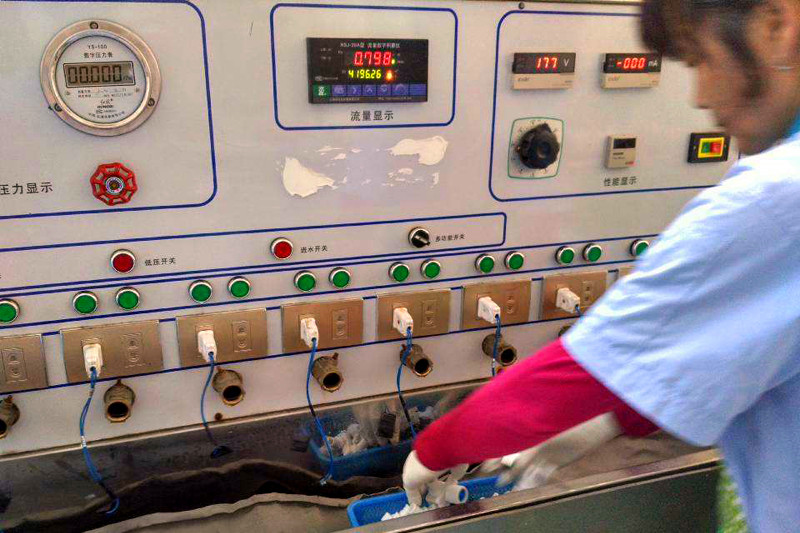

We apply the automation system and high precision measuring tools and

AOI are equipped to have dimensions controlled.

Including product surface treatment, electric static coating, hard

anodized process, sand blasting and grinding process.

We applied automated machines for mass production and increase the

elasticity of production.

We adopt high precision measure equipment to ensure the size of

received product is consist with our catalog.